Which sensors are used in automotive industry?

Exploring the Different Types of Sensors Used in the Automotive Industry

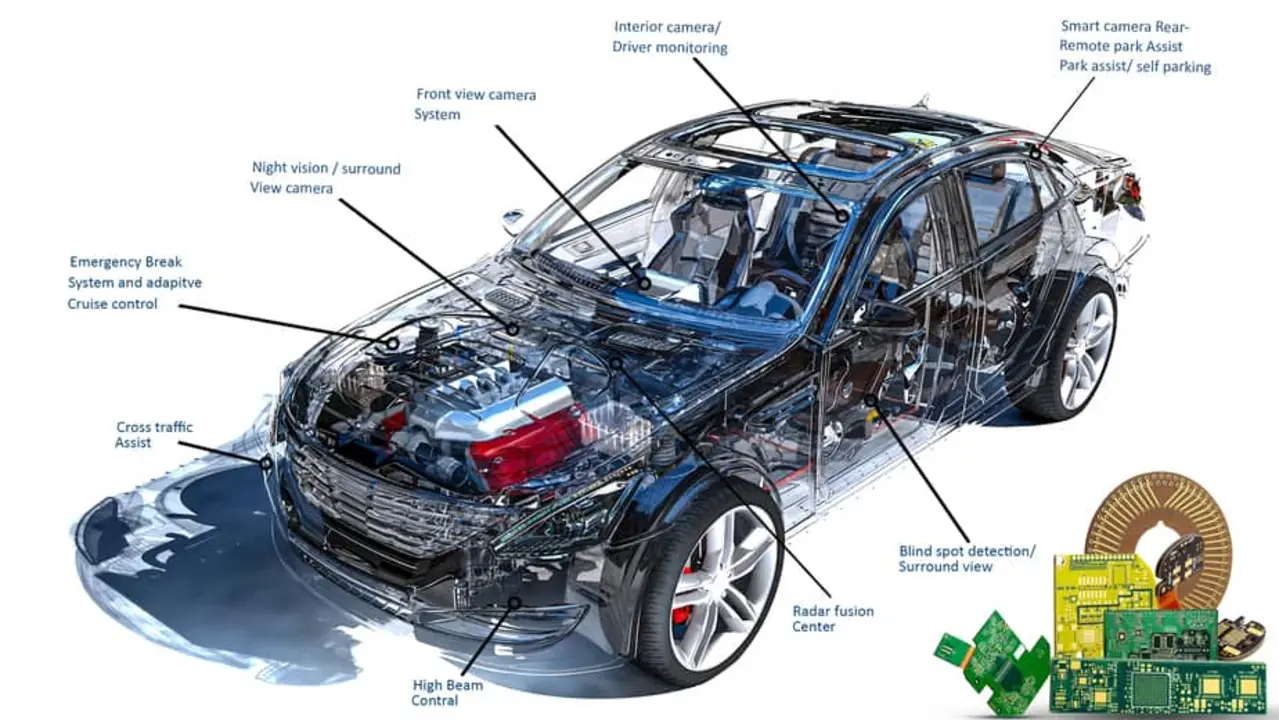

The automotive industry relies on a variety of sensors to make cars and other vehicles run efficiently and safely. Sensors measure various parameters such as pressure, temperature, and speed, and they are used in a wide range of applications from engine management to driver assistance. In this article, we'll explore the different types of sensors used in the automotive industry.

Pressure Sensors

Pressure sensors are used to measure the pressure of fluids, gases, and other materials in the car. They are used in the intake manifold to measure the amount of air going into the engine, as well as in the exhaust system to measure the pressure of exhaust gases. Pressure sensors are also used in the brake system to measure the pressure of the brake fluid. This information is used to control the power output of the engine and also to optimize the braking performance of the car.

Temperature Sensors

Temperature sensors are used to measure the temperature of various parts of the car. They are used in the engine to measure the temperature of the engine oil and coolant, as well as in the transmission to measure the temperature of the transmission fluid. Temperature sensors are also used in the exhaust system to measure the temperature of the exhaust gases. This information is used to control the power output of the engine and also to ensure that the car's components do not overheat.

Speed Sensors

Speed sensors are used to measure the speed of the car. They are used in the transmission to measure the speed of the wheels and also in the engine to measure the speed of the crankshaft. Speed sensors are also used in the suspension system to measure the speed of the suspension components, and they are used in the braking system to measure the speed of the brakes. This information is used to control the power output of the engine and also to optimize the braking performance of the car.

Position Sensors

Position sensors are used to measure the position of moving components in the car. They are used in the suspension system to measure the position of the wheels, in the steering system to measure the position of the steering wheel, and in the engine to measure the position of the crankshaft. This information is used to control the power output of the engine and also to optimize the steering and suspension performance of the car.

Acceleration Sensors

Acceleration sensors are used to measure the acceleration of the car. They are used in the transmission to measure the acceleration of the wheels, in the engine to measure the acceleration of the crankshaft, and in the suspension system to measure the acceleration of the suspension components. This information is used to control the power output of the engine and also to optimize the acceleration and braking performance of the car.

Understanding the Benefits of Using Sensors in Automotive Manufacturing

The automotive industry is constantly evolving, with new technology and advances in design and manufacturing being made every day. One of the most important innovations in the automotive industry is the use of sensors. Sensors are devices that can detect changes in the environment and provide information to a vehicle's control systems. This information can be used to improve the performance of the vehicle, reduce emissions and ensure the safety of passengers.

The use of sensors in automotive manufacturing is beneficial in a number of ways. Sensors can detect changes in the environment, allowing for more precise control over the vehicle's operation. This can result in improved fuel efficiency, as the vehicle can be more accurately controlled to get maximum performance. Sensors also help to reduce emissions, as they allow for more precise control over the fuel-air mixture and exhaust system.

Sensors are also important for safety. Sensors can detect changes in the environment and alert the driver if there is an issue. This can help to prevent accidents, as the driver can take corrective action before a dangerous situation arises. Additionally, sensors can be used to detect system malfunctions and alert the driver, allowing them to take corrective action before serious damage is done.

There are many different types of sensors used in automotive manufacturing. These include temperature sensors, pressure sensors, speed sensors, and motion sensors. Temperature sensors are used to monitor the temperature of the engine and other components, while pressure sensors are used to measure the pressure in the fuel system and other systems. Speed sensors are used to measure the speed of the vehicle and motion sensors are used to detect changes in the position of the vehicle.

The use of sensors in automotive manufacturing can help to ensure the safety of passengers and other road users. It can also help to reduce emissions, improve fuel efficiency, and optimize vehicle performance. By using sensors, automotive manufacturers are able to produce more reliable and efficient vehicles that are safe for everyone on the road.

Write a comment